Mã sản phẩm: Ma1 | Đã đọc: 1

Nhà sản xuất: SEL-EU

Hãng SEL Thiết bị đặc chủng cho phun cát được phân phối bởi MECO Công ty vật tư Thiết bị Việt Nam

Educt-O-Matic

Clemco's closed-circuit suction blast tool for spot cleaning, removing weld spatter, and deburring cut metal edges. Special attachments let you blast inside and outside corners, and on rough surfaces.

Educt-O-Matic Attachments:

• Flat Lip Attachment

• Serrated Attachment

• Edge Attachment

• Angle Attachment

• Master Adaptor

Download PDF

Hollo-Blast

The Clemco Hollo-Blast cleans the full 360 degree inside diameter of pipe to white metal finish. It operates without need of rotating the pipe or the tool. deposits such as rust, carbon millscale, coke and paint are easily removed. The Hollo-Blast will accommodate pipes from 2 inch to 12 inch I.D. and lengths up to 40 feet. Any abrasive (except aluminum oxide or silicon carbide) 20 mesh or finer may be used. In operation, the proper model is attached to a pipe lance and connected to Clemco blast hose. The Hollo-Blast is inserted into the pipe, the Clemco blast machine is started and the Hollo-Blast is manually pushed through the pipe. Abrasive hits the tungsten carbide deflector tip and fans out to clean the 360 degree interior. Air will blow spent abrasive and contaminants out of the pipe. The rate of cleaning depends on deposits being removed. Hollo-Blast is available with 1/2 inch or 5/8 inch nozzles. Standard HB-1 delivered with 1/2 inch nozzle. Air consumption, 1/2 inch 200 CFM, 5/8 inch 350 CFM.

Model HB-1

Hollo-Blast with 1/2 inch nozzle and tungsten carbide tip

Model HB-2

Hollo-Blast with 5/8 inch nozzle and tungsten carbide tip

Model HBB

Hollo-Blast with 1/2 inch nozzle and boron carbide tip

Model HBC-1

Centering Collars mount on Hollo-Blast to accommodate pipes from 3 inch to 5 inch I.D. in 1/2 inch increments

Model HBC-2

Centering Carriages is adjustable between 5 inch and 12 inch I.D. The lightweight aluminum carriage is quickly adjusted by knurled locknuct

Internal Pipe Cleaning Tool

Hollo-Blast Jr.

The Hollo-Blast Jr. is designed to clean pipe or tubing from 3/4 inch to 2 inch I.D. in 1/4 inch and 1/2 inch increments. The tool is mounted on 3/8 inch pipe lance for the length of tubing to be cleaned. A tungsten carbide lined reducer adapts the 3/8 inch lance to standard straight 1-1/4 inch thread for attachment to blast machine hose. Operation of the Hollo-Blast Jr. is the same as Hollo-Blast. Air consumption is 80 CFM. Recommended abrasive size is 30 mesh or finer.

Spin-Blast

The Clemco Spin-Blast is (a highly specialized attachment connected to the end of a pressure blast machine hose) specifically designed to restore any type of pipe to white metal clean without need of rotating pipe. With the complete removal of virtually any contaminant and with a highly desirable "tooth", the interior pipe surface is superbly prepared for the application of long-life coatings. Applicable for pipe sizes ranging from 8 inch to 36 inch I.D. the unit is a high production favorite of refineries, pipe liners, chemical producers, water and gas companies.

The Spin-Blast can be used with all common abrasives except aluminum oxide and silicon carbide. Simple preventive maintenance allows low-cost operation. Three nozzles of varied orifices and centering (two) carriages are available to accommodate pipes from 8 inch I.D. to 36 inch I.D. Either carriage is quickly adjustable for any diameter within the size range.

The Spin-Blast is connected with 1-1/4 inch pipe lance to a standard Clemco blast machine . Preferably the lance should be the length (up to 40 ft.) of the pipe being cleaned. To operate, the Spin-Blast is first pushed through the length of the pipe while the blast machine is idle. The air is fed from the blast machine which starts the blast head rotating. With full rotating speed quickly obtained, the abrasive control valve on the Clemco blast machine is opened. When the abrasive ejects from the spinning nozzle then the blasting is is progress, signaling the operator to withdraw the tool to clean the entire pipe length. Blasting speed is determined by the specific cleaning requirements. Standard unit delivered with 1/4 inch orifice by 1-3/4 inch long nozzles.

Portable Suction Blast Tool

Power Gun

The Clemco Power Gun is a suction blast tool designed for dry abrasive blasting where the air supply is limited or the job is small. The tool is lightweight and compact and ideal where setting up a conventional pressure blast machine would be awkward or inconvenient. The Power Gun can be used with all common media to clean or etch metal, clean masonry, etch glass, and other durable surfaces.

The optional heavy-duty plastic hopper holds and ample supply of media. The amount of media loaded will be dictated by the application and the location of the blast job.

Requirements for Operation

These items are required but not included with the Power Gun: Clean, dry, compressed air of sufficient volume to maintain pressure at the gun. Volume of air will depend upon the application and desired production rate. Suitable NIOSH-approved air-fed helmet for respiratory protection for the operator, as required by OSHA.

Blast media as suitable for the application. The Power Gun handles most fine media suitable for blasting. Consult distributor for media recommendation. OSHA recommends against the use of abrasive containing more than 1% free silica.

The optional heavy-duty plastic hopper holds an ample supply of media. The amount of media loaded will be dictated by the application and the location of the blast job.

Description of Operation

The tool simply connects to compressed-air and abrasive sources. The unique suction lance installed on the abrasive hose is partially submerged into a bag of media. Blasting begins when the operator depresses a lever on the gun. The tool operates on the principle of induction, where vacuum is created by the compressed air rushing past the point where the abrasive hose attaches to the gun. The vacuum draws abrasive through the hose into the gun, where it mixes with compressed air. The air-abrasive mix exits the gun and strikes the surface to be blasted.

Advantages

Lightweight, portable, easily transportable tool

Can be used with any media container or right out of the bag.

Simple setup—partially submerge suction lance into bag of abrasive

Easy to use and maintain

Popular applications

Touch-up work or re-blasting areas that may have failed inspection

Onboard ship

On a scaffold or other elevated or difficult to reach location

Small jobs

Wetblast Accessories

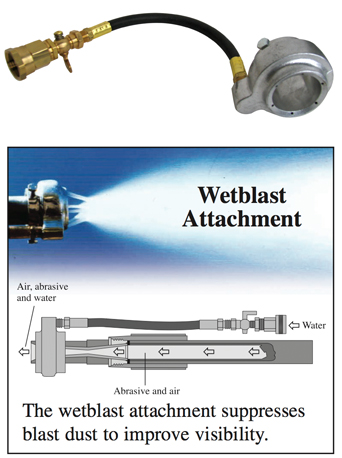

Wetblast Attachment

The Clemco Wetblast Attachment is a practical addition to conventional dry blasting. Used by building and painting contractors, shipyards and refineries, the Wetblast Attachment eliminates about 80% of the dust without lowering blast efficiency. It is uniquely suited to jobs in metropolitan areas or cleaning of masonry and concrete surfaces where excessive dust is generated. When used to blast steel surfaces, a rust inhibitor is recommended. The inhibitor may be sprayed on the surface immediately after blasting or can be mixed in a water tank equipped with a pump and sprayed through the wetblast head during blasting.

The Wetblast Attachment head, equipped with locking screws for mounting to the barrel of a nozzle, provides an operational advantage by mixing the water into the blast pattern just after air and abrasive leave the nozzle. This provides a larger blast pattern and eliminates the stoppages occurring with systems which mix or carry an abrasive/water slurry through the blast hose.

The uniform spray of the Clemco Wetblast Attachment is achieved by six 3/32 inch water jets which surround the nozzle and direct the water flow to a point 3 inches in front of the nozzle. As the water hits the air/abrasive stream it atomizes to envelop the abrasive particles. The water volume is metered by a full flow petcock located at the blast head. Pressure ranges of 30 lbs. to 60 lbs. (city water pressure) are acceptable. 50 ft. x 1/4 inch I.D. water hose is available for use with Wetblast Head. Hose fittings attach to standard water hose or faucet.

Wetblast Accessories

Wetblast Injector System

Clemco’s Wetblast Injector System adds the dust-suppressing power of water to any pressure blast machine. The Wetblast injects a small amount of water into the high-velocity abrasive/air stream just before the nozzle.

This hard-hitting mixture of water and abrasive cleans and keeps dust levels under control.

The Wetblast System introduces water into the abrasive/air stream before it passes through the nozzle orifice. This results in a complete wetting of each abrasive particle, unlike with water ring systems. The Wetblast controls airborne dust far better than water ring systems.

Operation

The power behind Clemco’s Wetblast Injector rests in our exclusive 10:1 pump. It uses compressed air to inject water into the high-velocity abrasive/air stream at the nozzle. A single pump can easily operate two nozzles, each with independent controls. Simply purchase an additional nozzle adaptor and add one more hydraulic hose to the water outlet.

The Wetblast Injector System requires no electric power, so there are no wires and no connections to short or shock.

Because the Wetblast Injector has its own pump and uses relatively small amounts of water, any source of clean water will work — household tap, water tower, or low-lying tank.

A regulator and pressure gauge, mounted inside the control box, controls water pressure. The operator adjusts the water volume with a fine-thread needle valve at the nozzle.

The versatile Wetblast Injector lets the operator blast with wet or dry abrasive. When the machine is equipped with an abrasive cut-off system, the operator can rinse the surface with air and water, then dry the surface with high-pressure air.

Applications

A blast system with Clemco’s Wetblast Injector quickly cleans structural steel to any degree of cleanliness from brush-off to white metal. After blasting, the water-and-air rinse removes soluble salts and other corrosives that can cling to the surface. If flash rust is a problem, the pump can siphon clean water from a static-holding tank that contains a premixed rust inhibitor solution to retard rust development on exposed steel.

Thiết bị đặc chủng cho phun cát - Special Equipment -